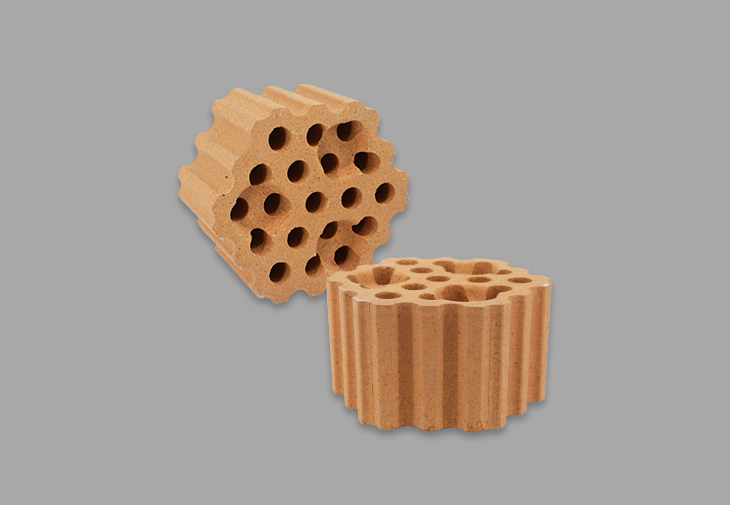

Highland Refractory presents High Alumina Checker Bricks, engineered for high-temperature applications. Our Standard High Alumina Checker Brick offers exceptional thermal stability with a high alumina content, making it ideal for use in furnaces and kilns. For clients with specific requirements, our Custom High Alumina Checker Bricks are tailored to meet unique design needs, ensuring optimal fit and performance. The High Purity High Alumina Checker Brick is perfect for industries requiring superior resistance to molten metal and extreme heat, while our Heat-Resistant High Alumina Checker Bricks excel in energy-intensive environments. These bricks enhance heat retention, minimize energy loss, and reduce maintenance costs, providing businesses with long-lasting performance and improved operational efficiency. Choose Highland Refractory for high-quality, cost-effective solutions that support your business growth and productivity.

Checker bricks are heat transfer media used in the regenerative chambers of blast furnaces and hot blast stoves.

Checker bricks are heat transfer media used in the regenerative chambers of blast furnaces and hot blast stoves.

As a prominent High Alumina Checker Brick manufacturer, Highland Refractory has been a trusted name in the industry since 1990. Our advanced production lines and skilled workforce of over 1,100 employees allow us to fulfill large orders quickly and efficiently, ensuring your project timelines are met. We offer High Purity High Alumina Checker Bricks, known for their exceptional heat resistance and thermal shock resistance, ideal for high-temperature applications in industries such as steel, cement, and ceramics. With competitive pricing compared to European and American brands, we bring you high-quality products at a more affordable rate without compromising performance.

Contact us

Our commitment to quality is reflected in our adherence to international standards and comprehensive certifications. Whether you need Heat-Resistant High Alumina Checker Bricks for extreme heat environments or Slag-Resistant High Alumina Checker Bricks for molten metal protection, we have the expertise to meet your needs. We understand the unique challenges faced by global buyers and end-users and work closely with you to deliver customized solutions. From customized sizes to specific material properties, we are equipped to meet the most demanding specifications of refractory applications.

Contact us

At Highland Refractory, we are not just a supplier; we are a partner that understands the specific needs of your industry. We specialize in thermal shock-resistant High Alumina Checker Bricks and other high-performance refractories like casting materials, fire bricks, and high alumina bricks. Our global presence ensures we are familiar with your market’s needs and provide reliable, tailored products that support your operations. Choose us for efficient, cost-effective solutions that cater to all your refractory requirements with exceptional quality and performance.

Contact usHighland Refractory’s High Alumina Checker Brick is designed to withstand the most demanding high-temperature environments. Our Standard High Alumina Checker Brick boasts an exceptional refractoriness of up to 1750°C, ensuring stability even in extreme conditions. With a cold crushing strength of 40 MPa (min), it provides outstanding mechanical resistance, making it ideal for furnaces and kilns exposed to high thermal stress. In addition to thermal shock resistance, these bricks offer superior slag resistance, ensuring durability in molten metal contact. The High Purity High Alumina Checker Brick excels in reducing impurities, offering excellent protection against chemical corrosion, which is crucial in steel and cement industries.

To meet diverse industrial needs, Highland Refractory offers both Standard High Alumina Checker Bricks and Custom High Alumina Checker Bricks tailored to specific furnace structures. Our standard sizes include 230x114x75 mm, suitable for most common applications. For more specialized equipment, we provide customized dimensions to match the shape and size of your kiln or furnace, helping you avoid costly modifications to existing machinery. This flexibility allows us to accommodate a wide variety of thermal processing systems, ensuring optimal fit and performance without the need for costly equipment alterations or delays.

Our Heat-Resistant High Alumina Checker Bricks are built for extreme high-temperature environments. With excellent insulation and high-temperature resistance, they are ideal for use in ceramic kilns, cement rotary kilns, blast furnaces, and incinerators. These bricks can easily handle temperatures ranging from 1400°C to 1750°C, making them suitable for industries such as steel, ceramics, non-ferrous metal processing, and cement. Their low thermal conductivity ensures minimal energy loss, which is crucial for industries focused on energy efficiency and cost reduction. By matching the material properties to your furnace’s thermal needs, we help you achieve optimal operational performance.

At Highland Refractory, we adhere to rigorous quality standards to ensure the reliability of our products. Our High Alumina Checker Bricks are manufactured in compliance with ISO 9001:2015 and meet European CE standards, guaranteeing high-quality products that meet international requirements. Our quality assurance system includes full-process monitoring, ensuring that each brick undergoes thorough inspection and testing before delivery. By choosing our bricks, you can be confident in their performance and compliance, eliminating concerns about imported product quality. Trust in Highland Refractory to provide products that not only meet but exceed industry standards.

At Highland Refractory, we understand the challenges that international buyers face when importing High Alumina Checker Bricks and other refractory materials. To ensure your products arrive in perfect condition, we offer tailored packaging solutions. For standard bricks like High Purity High Alumina Checker Bricks and Heat-Resistant High Alumina Checker Bricks, we use IPPC wooden pallets, corrugated boxes, and stretch film to prevent damage during transit. For fragile items like Thermal Shock-Resistant High Alumina Checker Bricks, we implement extra protection with moisture-resistant liners to ensure safe delivery.

Our domestic and international logistics are designed to keep you informed and satisfied. We handle container shipments and box truck deliveries with ease, ensuring timely exports and providing all the necessary customs clearance documents, including commercial invoices and packing lists.In case of any shipping damage, we offer free replacements and real-time tracking to keep you updated on the progress of your order. Our emergency response system guarantees fast resolution for urgent orders, ensuring smooth operations from start to finish. Trust Highland Refractory for reliable, secure, and efficient international shipping.

1. Domestic: 5-layer cartons (20–25 bricks) on 1200×1000mm pallets, stretch-wrapped;

2. Export: moisture-proof cartons + IPPC pallets + desiccant/labels;

3. Transport: domestic box trucks (≤60km/h), export containers (15cm gaps);

4. Loading/unloading: forklifts with pads; custom foam for irregular bricks (damage rate ≤0.5%);

5. After-sales: free replacement (photo verification within 24h); storage manual included.

Backed by decades of expertise, Highland Refractory delivers tailored refractory brick solutions across steel, cement, glass, and petrochemical industries. Trusted by global manufacturers, our products ensure long service life, efficiency gains, and cost savings—with on-site technical support to guarantee optimal performance for every client.

In the steel industry, furnaces like blast furnaces and electric arc furnaces face extreme heat and aggressive environments, which can lead to rapid wear and tear on refractory materials. Highland Refractory’s High Alumina Checker Bricks are ideal for these high-stress environments. Our Heat-Resistant High Alumina Checker Bricks provide superior thermal stability and slag resistance, making them perfect for key areas such as steel-making furnaces and heat-retention chambers. These bricks are designed to handle high thermal shock, ensuring long-lasting performance and minimizing frequent maintenance costs, addressing the core challenge of durability and heat resistance.

In cement kilns and other building material production equipment, the need for materials that can withstand extreme temperatures while maintaining thermal efficiency is critical. Highland Refractory’s High Alumina Checker Bricks offer excellent thermal insulation properties, reducing energy loss in rotary kilns and cement kilns. Our Slag-Resistant High Alumina Checker Bricks can withstand molten slag, providing the longevity needed in heat-intensive firing processes. The bricks’ low thermal conductivity ensures energy efficiency, helping businesses reduce fuel costs and improve operational efficiency while maintaining high-temperature stability.

In the chemical industry, reactors and furnaces often face corrosive environments with high temperatures. Highland Refractory’s High Alumina Checker Bricks offer excellent protection in these high-heat, high-abrasion areas. Our High Purity High Alumina Checker Bricks are particularly effective in chemical reactors and high-temperature kilns, where they resist both thermal shock and corrosive substances. These bricks help maintain temperature stability and extend the life of your equipment, addressing the industry’s need for reliable and long-lasting refractories.

In the energy incineration industry, where waste-to-energy incinerators and thermal power plants operate at extreme temperatures, Highland Refractory’s High Alumina Checker Bricks offer the thermal protection needed. Our Heat-Resistant High Alumina Checker Bricks provide energy-efficient insulation, reducing heat loss and lowering fuel consumption. These bricks are ideal for areas like furnace linings and combustion zones, where they resist thermal shock and maintain structural integrity under continuous exposure to high temperatures. By reducing the frequency of maintenance and downtime, these bricks help energy plants operate more efficiently and cost-effectively.

At Highland Refractory, we ensure consistent quality and reliable performance for all our High Alumina Checker Bricks, including Standard High Alumina Checker Bricks and Custom High Alumina Checker Bricks. Our production process begins with rigorous raw material inspection, ensuring only high-quality components are used. Next, the materials are carefully molded and subjected to high-temperature sintering to achieve optimal strength and thermal resistance. Finally, each brick undergoes comprehensive final product testing, focusing on critical parameters such as thermal shock resistance and slag resistance.

Our ISO 9001-certified quality control system ensures that each batch meets global standards. We maintain full-process monitoring throughout production, checking key indicators like density, refractoriness, and thermal conductivity to guarantee consistent high performance. Whether you require High Purity High Alumina Checker Bricks for specific applications or Heat-Resistant High Alumina Checker Bricks, you can trust Highland Refractory to deliver products that meet your highest standards.

In industries like steel manufacturing and cement production, high-temperature furnaces often face issues with wear and tear due to extreme heat and molten slag. Highland Refractory’s High Alumina Checker Bricks are designed to withstand these harsh environments. Our Heat-Resistant High Alumina Checker Bricks and Slag-Resistant High Alumina Checker Bricks offer superior thermal stability and slag resistance, ensuring longer-lasting performance even in the most demanding conditions. These bricks are perfect for blast furnaces and rotary kilns, offering protection against both high heat and molten metal, reducing the need for frequent replacements and minimizing downtime.

Many industries face challenges in finding refractory materials that perfectly match the size and shape of their high-temperature equipment. Highland Refractory addresses this with our Custom High Alumina Checker Bricks, which can be tailored to fit the specific dimensions of your equipment. Whether it’s a furnace, kiln, or reactor, our customized solutions ensure optimal thermal insulation and thermal shock resistance, providing a seamless fit that eliminates the need for costly equipment modifications. This flexibility makes our products ideal for specialized industrial applications.

Refractory materials in high-temperature environments often experience frequent wear and short service life, leading to costly replacements and production interruptions. Our Standard High Alumina Checker Bricks are built for durability, offering a longer lifespan compared to other refractory materials. With their high thermal stability and resistance to thermal shock, they help extend the service life of kilns, furnaces, and heat exchangers, reducing maintenance costs. By investing in our high-quality bricks, businesses can significantly lower the total cost of ownership and increase operational efficiency.

In today’s competitive market, industries are increasingly focused on improving their energy efficiency and reducing their environmental footprint. Highland Refractory’s High Alumina Checker Bricks are designed to minimize heat loss and improve thermal insulation, helping industries like cement plants and glass furnaces reduce their energy consumption. Our Thermal Shock-Resistant High Alumina Checker Bricks are built to withstand the frequent temperature fluctuations common in industrial processes, further enhancing energy efficiency. These bricks not only improve operational performance but also contribute to sustainability, making them an ideal choice for eco-conscious companies looking to reduce their environmental impact.

Checker bricks are heat transfer media used in the regenerative chambers of blast furnaces and hot blast stoves.

Silicon carbide plates are mainly composed of silicon carbide (SiC) as the aggregate (with a content usually ≥ 80%).

Steel fiber wear-resistant castables are widely used in high temperature and wear-resistant environments in many industrial fields such as metallurgy, building materials, and chemicals.