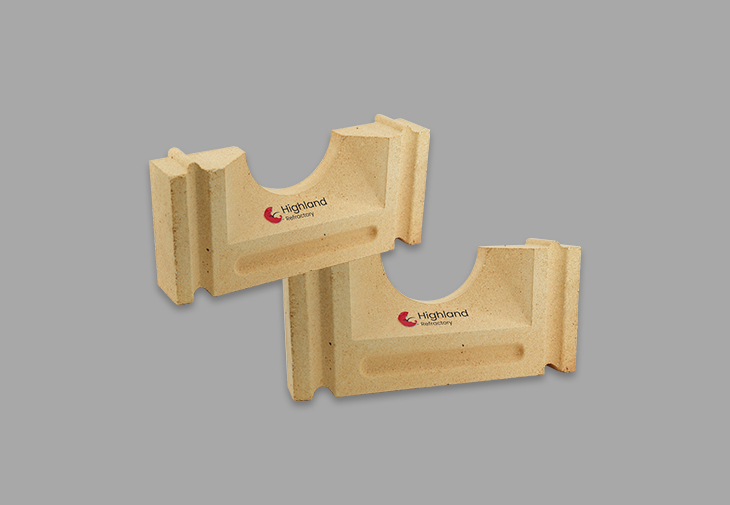

Highland Refractory offers premium High Alumina Specialty Bricks designed to meet the toughest industrial demands. With exceptional heat resistance up to 1750°C and thermal shock resistance, our bricks are perfect for furnaces, kilns, and reactors exposed to extreme temperatures. These bricks are made from high-purity alumina, ensuring superior slag resistance and long-lasting performance in industries such as steel, cement, and glass production. Whether you need High Alumina Specialty Bricks for sale or High-Alumina Special-Shaped Bricks for sale, our solutions are customizable to fit your unique equipment and operational needs. The Heat-Resistant High Alumina Specialty Bricks reduce maintenance costs, improve thermal efficiency, and extend the lifespan of your high-temperature equipment. With Highland Refractory, you get durable, cost-effective solutions that enhance your operations.

As a trusted manufacturer of High Alumina Specialty Bricks, Highland Refractory has been at the forefront of the refractory industry since 1990. Our advanced production lines, supported by a skilled workforce of over 1,100 employees, enable us to efficiently meet the high demand for Heat-Resistant High-Alumina Specialty Bricks and Thermal Shock-Resistant High-Alumina Specialty Bricks. With our comprehensive facilities, we provide fast and reliable production for a wide range of refractory products, including fire-resistant specialty bricks and customized solutions tailored to your unique requirements.

Contact us

At Highland Refractory, we understand the specific needs of international buyers and end-users in industries such as steel, cement, glass, and ceramics. Our bulk high-alumina specialty bricks imported from China are designed to withstand extreme conditions like high heat and thermal shocks, making them ideal for furnaces, kilns, and other high-temperature environments. We offer customized sizes and specialized formulations to match the exact requirements of your equipment, ensuring seamless integration and long-lasting performance.

Contact us

With over three decades of expertise, we pride ourselves on delivering high-quality refractory bricks at competitive prices compared to Western brands. Our products meet global quality standards and are backed by certifications, giving our international customers the confidence in their long-term performance. Whether you need standard or custom high-alumina specialty bricks, we provide cost-effective, durable solutions designed to improve thermal efficiency and reduce maintenance costs. Highland Refractory ensures a reliable supply for your refractory needs, making us a trusted partner for industries worldwide.

Contact usHighland Refractory’s High Alumina Specialty Bricks are engineered to withstand the most demanding high-temperature applications. These bricks feature a refractoriness of up to 1750°C, making them ideal for furnaces, kilns, and reactors. With a cold crushing strength of 50 MPa (min), they provide excellent mechanical resistance. Our bricks are designed to handle thermal shock, ensuring durability even in environments with rapid temperature fluctuations. Heat-resistant High-Alumina Specialty Bricks offer superior thermal stability, which is essential for industries like steel, cement, and ceramics, where high-temperature resilience is a critical factor.

We offer both standard and customized sizes of High Alumina Specialty Bricks to ensure a perfect fit for your equipment. Standard dimensions include 230x114x75 mm, commonly used in many industrial applications. However, we understand that each operation is unique, and we provide custom high-alumina special-shaped bricks for sale, tailored to the specific geometry of your furnace or kiln. Our flexible sizing options allow you to avoid costly equipment modifications and ensure a seamless fit for your operational needs, providing you with optimal thermal performance.

Our High Alumina Specialty Bricks are built to excel in high-temperature environments ranging from 1400°C to 1750°C. These bricks are perfect for industries that demand thermal shock resistance and slag resistance, such as steel production, cement manufacturing, glass melting furnaces, and energy incineration. Whether used in combustion chambers or heat-retention zones, our Thermal Shock-Resistant High-Alumina Specialty Bricks can withstand the harshest conditions while maintaining their structural integrity, helping to reduce downtime and improve operational efficiency in high-temperature processing environments.

At Highland Refractory, we adhere to the highest international standards. Our High Alumina Specialty Bricks are produced in accordance with ISO 9001:2015 quality management systems and meet CE standards for European markets. This guarantees that our bricks comply with rigorous performance and safety standards. By choosing our products, you can be confident that you are receiving quality-assured refractories that meet global standards. This eliminates concerns about imported product quality and ensures that your operations run smoothly with reliable, high-performance materials.

At Highland Refractory, we ensure a smooth and reliable international logistics experience for all our clients purchasing High-Alumina Specialty Bricks. For standard fire bricks and insulation bricks, we use IPPC-certified wooden pallets, corrugated cartons, and stretch film to securely package each order, preventing damage during transit. For more delicate products like High-Alumina Special-Shaped Bricks, we add moisture-proof liners for extra protection, ensuring they reach you in perfect condition.

We offer flexible domestic and international shipping solutions, including box truck delivery within China and container shipments for exports. All necessary customs clearance documentation, such as commercial invoices and packing lists, are provided to facilitate a seamless clearing process.

In case of any transit damage, we offer free replacements and real-time logistics tracking services, keeping you informed throughout the shipping journey. We understand the urgency of high-temperature refractory materials, so our emergency response mechanism ensures fast processing for urgent orders. Whether you’re buying Heat-Resistant High-Alumina Specialty Bricks or Thermal Shock-Resistant High-Alumina Specialty Bricks, we prioritize the protection and timely delivery of your order, providing you with complete confidence in our service.

1. Domestic: 5-layer cartons (20–25 bricks) on 1200×1000mm pallets, stretch-wrapped;

2. Export: moisture-proof cartons + IPPC pallets + desiccant/labels;

3. Transport: domestic box trucks (≤60km/h), export containers (15cm gaps);

4. Loading/unloading: forklifts with pads; custom foam for irregular bricks (damage rate ≤0.5%);

Backed by decades of expertise, Highland Refractory delivers tailored refractory brick solutions across steel, cement, glass, and petrochemical industries. Trusted by global manufacturers, our products ensure long service life, efficiency gains, and cost savings—with on-site technical support to guarantee optimal performance for every client.

In the steel manufacturing industry, key equipment like blast furnaces, electric arc furnaces, and steel ladles face the challenge of withstanding extreme temperatures and molten slag. Highland Refractory’s High Alumina Specialty Bricks are designed to meet these demands. Our Heat-Resistant High Alumina Specialty Bricks offer superior thermal insulation and slag resistance, making them ideal for furnace linings and heat-retention zones. The Thermal Shock-Resistant High Alumina Specialty Bricks ensure durability even under temperature fluctuations, minimizing wear and reducing downtime, which is crucial for improving operational efficiency and reducing maintenance costs.

In the non-ferrous metals industry, equipment such as smelting furnaces, refining furnaces, and slag pots require refractories that can withstand high temperatures and corrosive molten metals. Highland Refractory’s High Alumina Specialty Bricks are perfectly suited for these applications. Our High-Purity High Alumina Specialty Bricks provide excellent resistance to slag erosion and thermal shock, ensuring long-lasting performance in smelting and refining processes. Their high thermal conductivity and slag resistance make them the optimal choice for furnaces dealing with molten metals like aluminum and copper.

In the building materials industry, equipment such as cement kilns, glass furnaces, and ceramic kilns operate under extreme heat and stress, requiring refractories that offer both thermal insulation and strength. Highland Refractory’s High Alumina Specialty Bricks are designed to withstand the challenges faced by these industries. Our Heat-Resistant High Alumina Specialty Bricks are perfect for kiln linings, providing outstanding thermal efficiency while minimizing heat loss. With superior resistance to both thermal shock and abrasion, our bricks offer long-term durability, reducing maintenance and energy consumption for industries like cement, glass, and ceramics.

In the energy and incineration industry, coke ovens, fluidized bed boilers, and carbon roasting furnaces are exposed to extreme temperatures and harsh environmental conditions. Highland Refractory’s High Alumina Specialty Bricks are engineered to endure these environments. Our Slag-Resistant High Alumina Specialty Bricks provide excellent protection in furnace linings, while the Thermal Shock-Resistant High Alumina Specialty Bricks ensure performance under rapid temperature changes. These bricks enhance thermal efficiency and energy savings in waste-to-energy plants and industrial boilers, helping to reduce operating costs and improve system reliability.

At Highland Refractory, we maintain a transparent and precise manufacturing process to ensure the highest quality of our High Alumina Specialty Bricks. The process begins with raw material inspection, followed by molding, high-temperature sintering, and final product testing. Each stage is carefully monitored to ensure that the bricks meet stringent performance standards.

Our Heat-Resistant High-Alumina Specialty Bricks and Thermal Shock-Resistant High-Alumina Specialty Bricks undergo rigorous testing to confirm slag resistance, thermal stability, and compressive strength. With our ISO 9001-certified quality management system, we implement full-process monitoring and key performance indicators to ensure product consistency and reliability. Whether you’re purchasing Bulk High-Alumina Specialty Bricks Imported from China or need customized solutions, our quality control system guarantees the durability and reliability of every brick, giving you peace of mind with every shipment.

In industries like steel and cement manufacturing, furnaces face extreme temperatures and the threat of molten slag, causing rapid wear on refractory materials. Highland Refractory’s Heat-Resistant High-Alumina Specialty Bricks are engineered to endure these harsh environments. With exceptional slag resistance and high thermal stability, our bricks ensure longer service life in high-temperature areas such as blast furnaces and kilns. By providing superior protection against slag erosion, our bricks minimize maintenance costs and downtime, helping you maintain continuous production without the frequent need for replacements.

Many industrial processes face challenges when it comes to finding refractory materials that perfectly match the dimensions of specialized equipment. Highland Refractory’s High-Alumina Special-Shaped Bricks are customizable to meet your specific needs. Whether you’re working with furnaces, heating chambers, or kilns, we provide tailored solutions that fit seamlessly into your equipment, eliminating the need for expensive equipment modifications. This ensures optimal performance and thermal efficiency without the headache of “ill-fitting” materials. Our custom high-alumina specialty bricks for sale make it easier for you to address unique industrial needs while improving performance.

In industries such as glass and ceramics, high wear and tear on refractories can result in frequent replacements and increased operational costs. Highland Refractory’s High-Alumina Specialty Bricks provide long-lasting performance due to their thermal shock resistance and durability. Our bricks are designed to withstand rapid temperature fluctuations, ensuring a longer lifespan and reduced downtime. By investing in our thermal shock-resistant high-alumina specialty bricks, you reduce the need for frequent replacements and maintenance, leading to significant cost savings in the long run. This is crucial for industries where operational efficiency is directly tied to product quality.

In today’s environmentally-conscious market, industries are looking for materials that offer energy savings while being eco-friendly. Highland Refractory’s High-Alumina Specialty Bricks contribute to thermal insulation and energy efficiency, helping industries like cement production and power plants reduce energy consumption. Our fire-resistant specialty bricks help lower heat loss and improve the thermal efficiency of kilns, furnaces, and other high-temperature equipment. By reducing the amount of fuel required to maintain temperature, our bricks not only improve the environmental footprint but also reduce operational costs. Sustainable and cost-effective, our bricks are the ideal choice for businesses seeking to reduce both energy use and environmental impact.