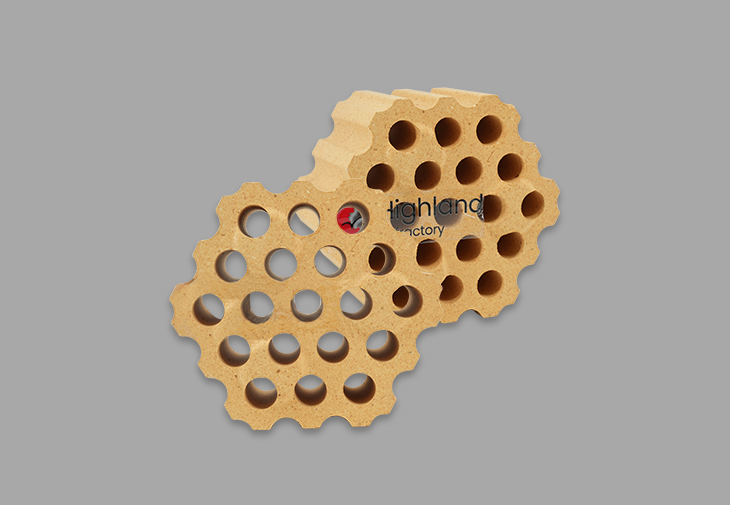

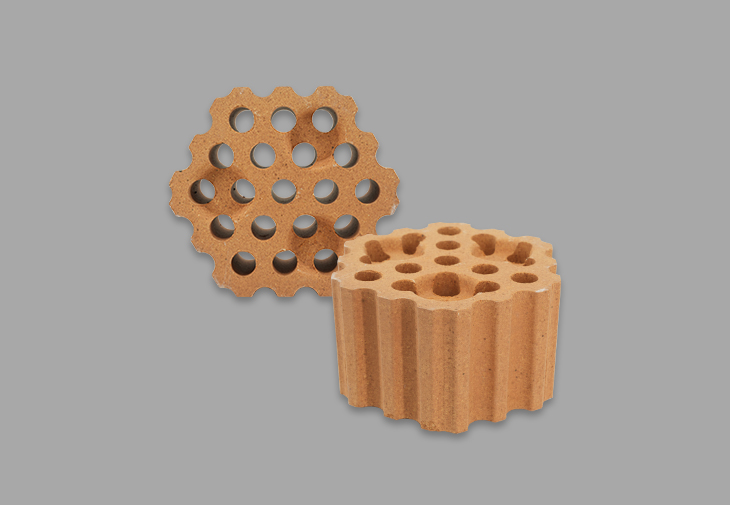

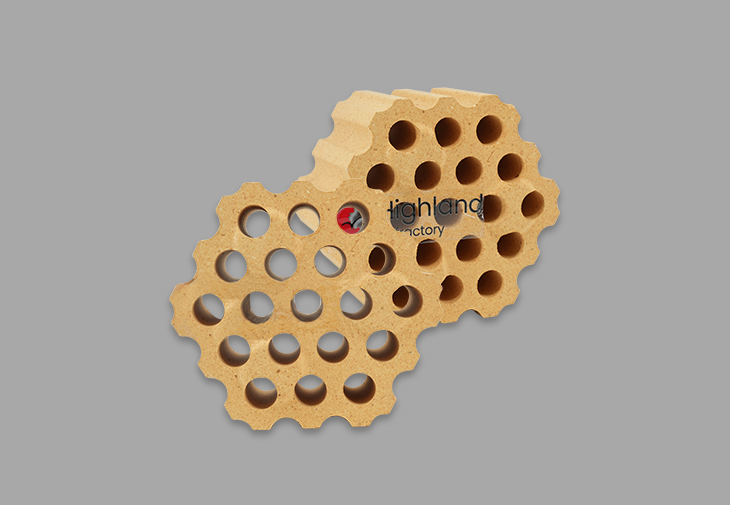

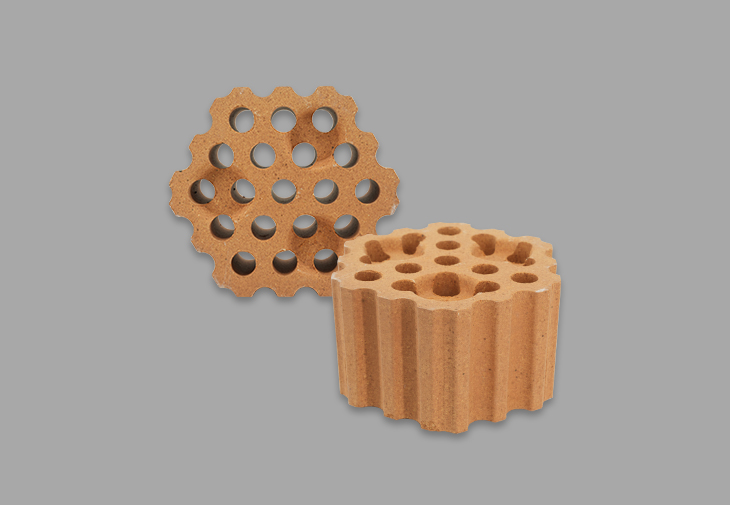

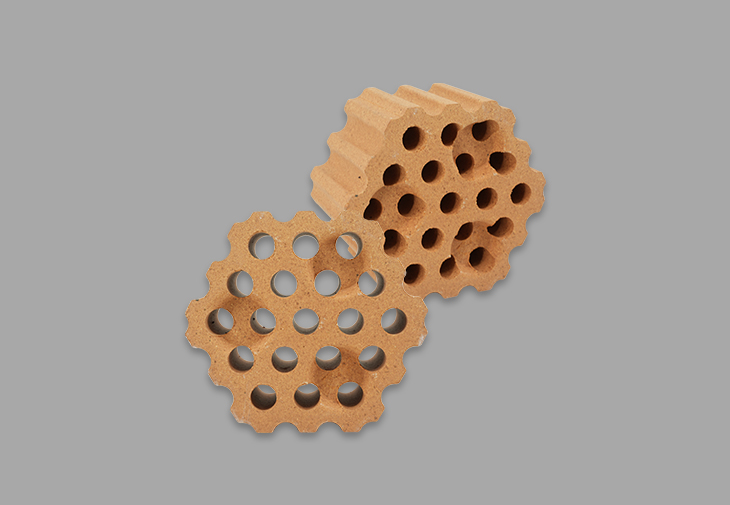

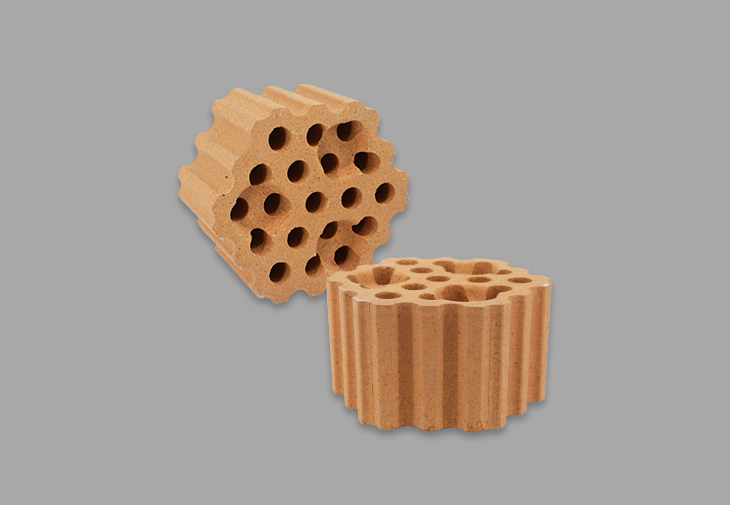

High-alumina checker bricks are mainly made of bauxite clinker and other materials after high-temperature mixing, forming, drying and sintering.

Its main component is alumina. It is a heat transfer and heat storage body with many excellent thermal characteristics such as strong heat exchange capacity, large heat storage area, smooth ventilation and low resistance.

(1) Good volume stability;

(2) Excellent high temperature load creep performance;

(3) High density, low porosity;

(4) Strong heat exchange capacity and large heat storage area;

(5) Strong pressure resistance and good corrosion resistance;

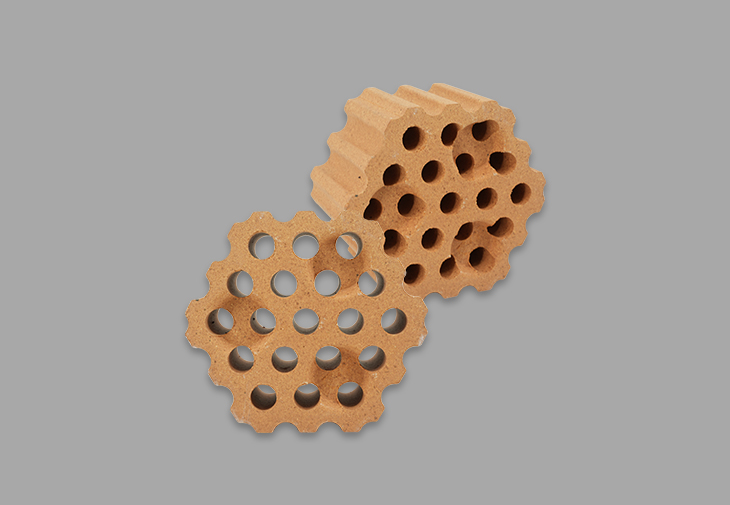

(1) Mainly used for the partition walls of the carbonization chamber and combustion chamber of the coke oven, the heat storage chamber and slag chamber of the steelmaking open hearth furnace, the soaking furnace, the refractory materials of the glass melting furnace and the vault and other load-bearing parts of the ceramic firing kiln.

(2) Also used for the high-temperature load-bearing parts of the hot blast furnace and the top of the acid open hearth furnace.

|

Item |

High Alumina Checker Brick |

Micro-expansion high alumina bricks |

|||

|

Grade |

RSGL-75 |

RSGL-65 |

RSGL-55 |

RSWPL-75 |

|

|

Chemical element content% |

Al2O3≥ |

75 |

65 |

55 |

75 |

|

Fe2O3≥ |

2.0 |

2.0 |

2.5 |

2.0 |

|

|

Refractory degree/℃,≥ |

1790 |

||||

|

Load softening start temperature/℃,0.2MPa |

1500 |

1470 |

1450 |

1520 |

|

|

Apparent porosity/%≤ |

20 |

22 |

23 |

19 |

|

|

Compressive strength at room temperature/MPa,≥ |

60 |

55 |

40 |

70 |

|

|

Volume density/(g/cm3),≥ |

2.5 |

2.4 |

2.3 |

2.6 |

|

|

Linear change rate/%,(1500℃×2h) |

0—0.2 |

0—-0.2 |

±0.2 |

0-0.6 |

|

(1)By Al₂O₃ content: LZ-55 (≥55%, for hot blast stoves), LZ-75 (≥75%, for electric furnace tops), LZ-82 (≥82%, for blast furnace ceramic cups).

(2)Functional types: High-alumina checker bricks (heat exchange for hot blast stoves), phosphate-impregnated high-alumina bricks (wear-resistant for waste incinerators), and custom special-shaped bricks (molds ready in 3 days for small batches).

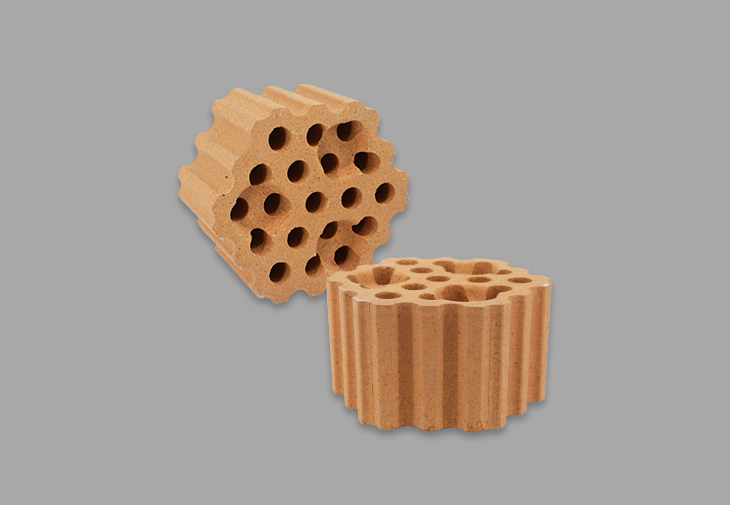

(1)High temperature resistance: Refractoriness up to 1790℃, withstanding long-term use at 1200-1600℃.

(2)Precision & durability: CNC pressing (±1mm tolerance) + tunnel kiln sintering (20% energy saving via waste heat recovery), cold crushing strength ≥50MPa.

(3)Cost-efficiency: 95%+ waste recycling rate, raw material localized procurement (30% lower cost than imports).

(1)Steel industry: Blast furnace linings (cooperated with a Hebei steel mill, service life extended to 3 years, 6 months longer than peers).

(2)Cement industry: Kiln transition zones (resists thermal shock, ≥30 cycles at 1100℃).

(3)Glass industry: Glass furnace regenerators (LZ-82 bricks withstand 1790℃, reducing shutdowns).

| Aspect | High Alumina Bricks (Highland) | Insulation Bricks |

|---|---|---|

| Core function | High-temperature resistance + load-bearing | Only heat insulation (non-load-bearing) |

| Long-term temp resistance | 1200-1600℃ | ≤1200℃ |

| Bulk density | 2.15-2.5 g/cm³ | 0.6-1.3 g/cm³ |

| Application scenario | Kiln core parts (e.g., furnace linings) | Furnace insulation layers |

(1)Strength: 30-year experience, 2 production bases, annual output of 30,000 tons of high alumina bricks.

(2)Quality: ISO 9001/CE certified, 3-level quality control (raw material → small-batch test → full inspection).

(3)Service: 15-day delivery for custom orders, 24/7 video technical support for overseas clients.

(1)Performance: SiC content ≥85%, refractoriness up to 1900℃, 10x higher thermal conductivity than ordinary bricks.

(2)Synergy: Co-shipment with high alumina bricks (saves 30% freight).

(3)Customization: Molds for special-shaped silicon carbide bricks ready in 5 days, Suitable for ladle slag lines and petrochemical reactors.

For exports: Use EU-standard fumigated wooden crates + pearl cotton; for domestic sales: Use steel strip binding/lamination. Transport damage rate ≤ 0.8%, and a logistics tracking number will be provided.

Shaped high alumina bricks come with a 3-year warranty; free replacement for quality issues within the warranty period. Half-price inspection is available after the warranty expires.

We hold ISO 9001 and CE certifications (compliant with multiple domestic and international standards). Each batch undergoes three-level quality control (raw material inspection → small-batch testing → full inspection), and detailed test reports are provided.

Yes. We have a 2,300㎡ R&D center (cooperating with Luoyang Refractory Research Institute and Zhengzhou University). We can adjust raw material ratios (e.g., adding silicon carbide for high-temperature scenarios) and customize special-shaped bricks.

High alumina poly light brick is a high quality lightweight refractory material.

Mullite lightweight insulation brick is a high-quality insulation material.

Corundum - mullite brick refers to high purity or pure raw materials made of refractory products.

Low creep clay bricks have a low creep rate in high temperature environments and can maintain good shape and dimensional stability for a long time.

Silica-molybdenum bricks have high resistance to chemical erosion and excellent wear resistance, and are the preferred material for the transition zone and preheating zone of large cement kilns.

Made from industrial alumina and refractory kaolin as the main raw materials, produced through scientific formulation...